Registered Office: Via per Grumello 45/D, 24127, Bergamo, Italy

© Kirmek Srl - Vat number: IT03502870169

PRODUCTS

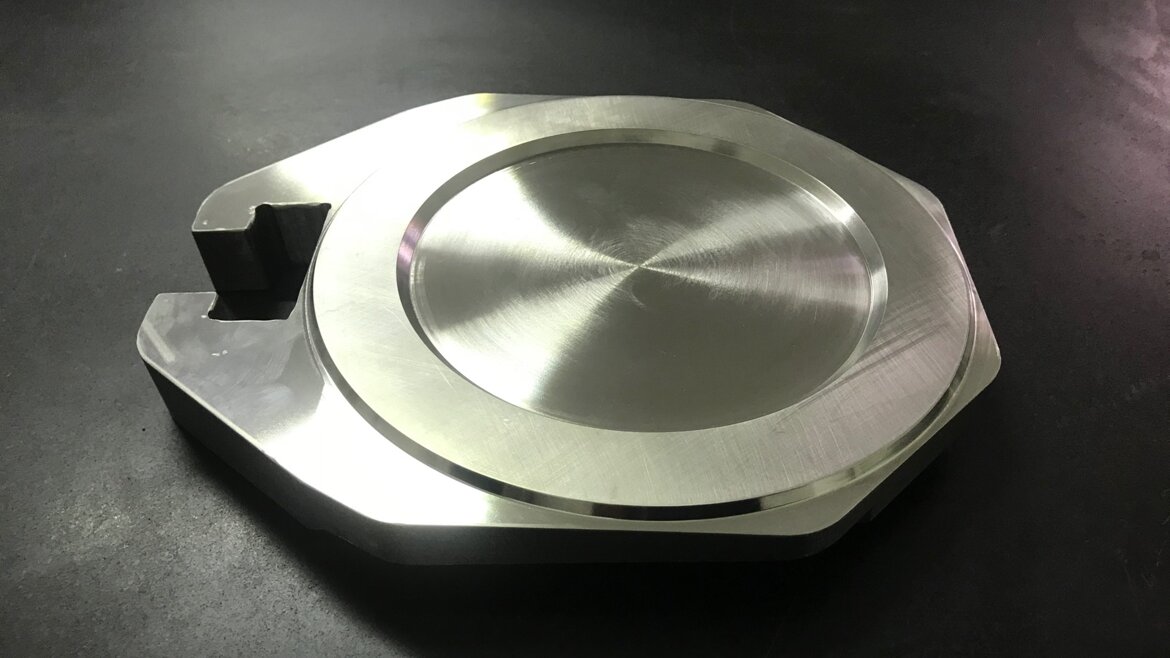

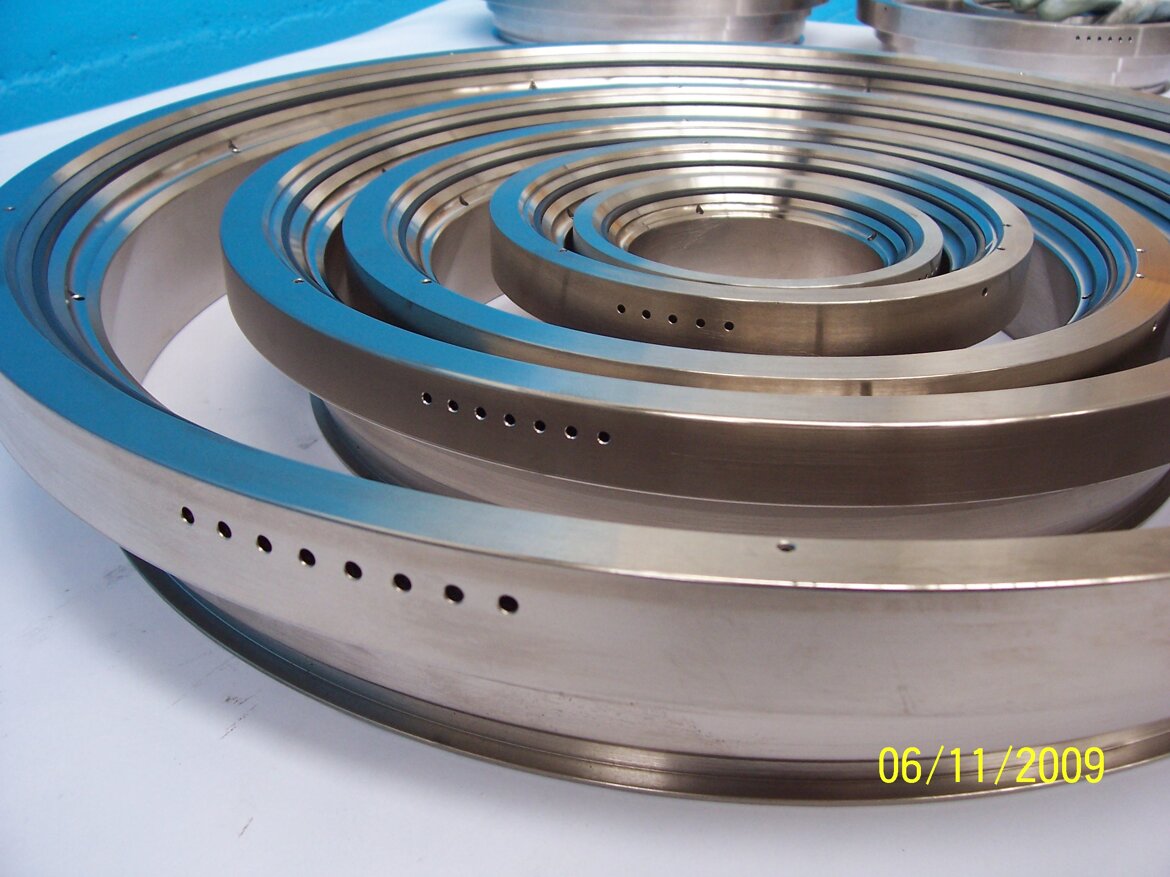

Kirmek produces valve components from ½" up to 72", and all the mechanical processing is made in-house.

The staff is capable of machining, turning, drilling and milling any kind of mechanical part, up to Ø2.000 mm and 1.200 mm height.

SURFACE TREATMENTS, COATINGS AND CLADDING

All these treatments are carried out by qualified suppliers.

- The nickel surface treatment is crucial for protecting the steel against the oxidation, the thickness of the surface treatment goes from 25 up to 75 micron, with an hardness of 500-600 HV up to 800-900 HV.

- The Tungsten Carbide Coating (TCC) is necessary for obtaining an excellent bond strenght, an high microhardness and density through the HVOF method, if it's required we can do the adaptation of the seat to the related ball.

- Overlays and claddings are widely used with metal to metal seats, all the overlays are done in accordance with WPS-PQR

qualifications, with the help of qualified welders, the common overlays are in Stellite, F316, F6A and Inconel.

SEATS WITH HARD INSERT

SEATS WITH SOFT INSERT

METAL-TO-METAL SEATS

A type of seat that Kirmek produces is based on the using of an hard insert in the groove on the sealing area.

Typical materials used are: PTFE enriched with different materials, DEVLON ®, PEEK, NYLON 6 MOS 2, KEL-F.

The choice of the material depends on:

-the temperature,

-the pressure,

-the fluid that pass through the pipeline.

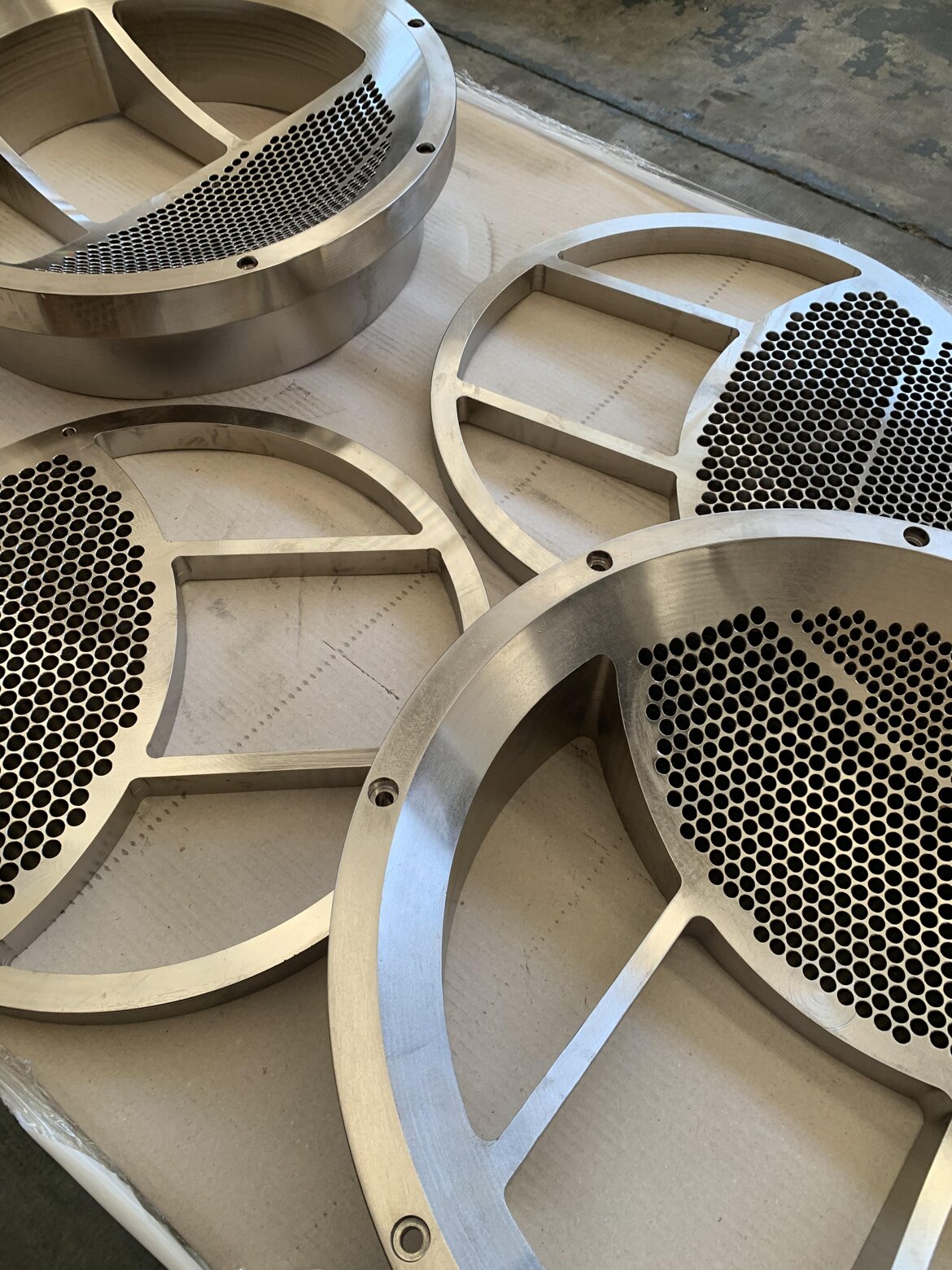

They represent the core business of Kirmek.

Kirmek has designed and manufactured the moulds for the production of DELTA RINGS and V-RINGS in FKM, FKM LT, HNBR compounds with AED (Anti Explosive Decompression) certification, all designed in house.

After the production of the delta rings, these ones will be assembled into the seats, in order to avoid every possibility of extrusion when the valve will be in working.

It's important to highlight the fact that all the seats with soft inserts are perfectly exchangeable with those of the competitors, in that way Kirmek can do also the service.

This type of seats is used in case of corrosive and/or abrasive fluids, simultaneously in presence of high temperatures and pressures.

Kirmek for this reason makes overlays on the sealing surface, in different kinds of materials, such as STELLITE and INCOLOY.

KIT SEATS + BALL

OTHER COMPONENTS

OTHER SECTORS

Besides seats, Kirmek has increased the production of other components, specially of OBTURATORS, including also the assembling of thethem into the bodyvalves.

Over the years, Kirmek Srl has produced hundreds of obturators from 2" up to 60" !

Kirmek Srl is able to supply other valve components, such as BALLS, BONNETS, DISKS, TRIMS, SEGMENT RINGS and CLOSURES.

Kirmek can also produce:

- Rubber-metal molding, for the Naval and Maritime sector;

- Threaded rings for the Energy sector, with extremely tight tolerances.

Kirmek can offer the kit seats + ball:

the grinding of the balls is done by qualified suppliers, whereas the mechanical process is done in-house.

STEEL USED

Only Italian and Western-European steel, in according to the specifications required, such as:

A105 / A350 LF2

AISI 410 - F6A

F304 - F316 - F321 - F347

INCONEL 625

INCOLOY 825

ALLOY X750

HASTELLOY C276

F44 - F51 - F53 - F55

F6NM

17.4 PH

XM 19

F11 - F22 - F91 - F92

A565 GR 616 HT

TITANIUM

MONEL K400 - K500

Registered Office: Via per Grumello 45/D, 24127, Bergamo, Italy

© Kirmek Srl - Vat number: IT03502870169